Low-Density Polyethylene, commonly known as LDPE, is a versatile and widely used thermoplastic polymer. LDPE sheets, a popular product derived from LDPE resin, are renowned for their flexibility, durability, and sustainability. In this blog, we will explore the world of LDPE sheets, highlighting their characteristics, numerous applications, and their role in promoting eco-friendly solutions.

Understanding LDPE Sheets

Low-Density Polyethylene (LDPE) is a type of plastic known for its low density, which imparts flexibility and excellent resistance to moisture. LDPE sheets are produced through an extrusion process that results in thin, flat sheets with varying thicknesses. These sheets are appreciated for their malleability and are used in a wide range of applications.

Applications of LDPE Sheets

Packaging: LDPE sheets are widely employed in the packaging industry for creating plastic bags, shrink wrap, and stretch films. Their flexibility and moisture resistance make them suitable for safeguarding a variety of products during storage and transit.

Agriculture: LDPE sheets find extensive use in agriculture as greenhouse films and mulch films. They create controlled environments for plant growth and provide protection against adverse weather conditions.

Construction: In the construction sector, LDPE sheets are used for vapor barriers and under-slab moisture protection. They help maintain the structural integrity of buildings by preventing moisture infiltration.

Manufacturing: LDPE sheets are integral in manufacturing industries. They are used for lining tanks, creating protective covers for machinery, and as anti-static or slip-resistant materials in various applications.

Medical and Healthcare: In the healthcare sector, LDPE sheets are employed in the production of medical packaging, medical device components, and disposable gloves.

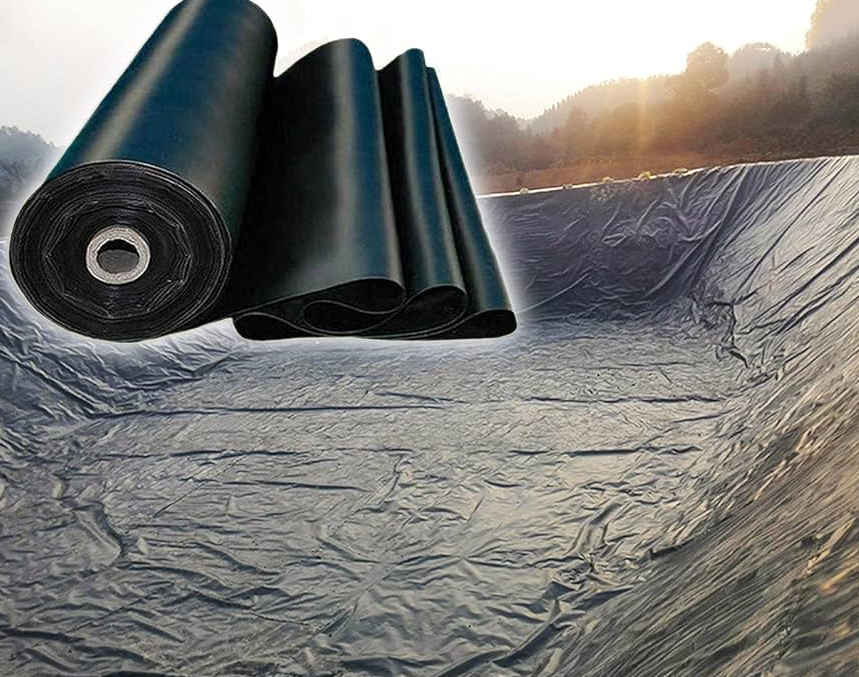

Environmental Protection: LDPE sheets play a role in environmental conservation. They are used to create products like pond liners, floating barriers, and liners for waste containment sites.

Benefits of LDPE Sheets

Flexibility: LDPE sheets are highly flexible, making them suitable for applications that require bending, shaping, or wrapping around various objects.

Moisture Resistance: These sheets are impermeable to moisture, making them ideal for applications where water or humidity resistance is crucial.

Chemical Resistance: LDPE is resistant to a wide range of chemicals, making it suitable for use in diverse environments.

Lightweight: LDPE sheets are lightweight and easy to handle, which simplifies installation and transportation.

Sustainability: LDPE is recyclable, and LDPE sheets can be reprocessed into new products. The recycling process for LDPE consumes less energy compared to producing new plastic from raw materials, contributing to environmental sustainability.

Eco-Friendly Aspects

LDPE sheets offer several eco-friendly benefits:

Recyclability: LDPE is highly recyclable, and many LDPE sheet manufacturers use recycled materials in their production processes, reducing the demand for new plastic.

Sustainable Agriculture: LDPE sheets are instrumental in modern agriculture, providing environmentally friendly solutions for crop protection, water conservation, and controlled growth environments.

Waste Management: LDPE sheets are used in waste containment and management, helping to prevent environmental contamination and safeguarding ecosystems.

The Future of LDPE Sheets: Sustainability and Innovation

The future of LDPE sheets is a promising one, driven by ongoing innovations and a growing commitment to sustainability. Here are some trends and developments we can anticipate:

Biodegradable LDPE: Researchers are actively working on developing biodegradable LDPE materials. These environmentally friendly alternatives have the potential to reduce the environmental impact of plastic waste significantly.

Recycling Advancements: The recycling of LDPE is expected to become more efficient and widespread. Innovations in recycling technologies will further reduce the carbon footprint associated with LDPE sheets, as more recycled materials are incorporated into new products.

Eco-Friendly Additives: Manufacturers are exploring the use of eco-friendly additives and fillers to enhance the sustainability of LDPE sheets. These additives can improve properties like UV resistance or flame resistance while maintaining environmental responsibility.

Customization: The versatility of LDPE allows for customization in terms of color, thickness, and additives. Manufacturers are likely to cater to specific customer needs by offering a broader range of options for tailored solutions.

Collaboration with Other Industries: LDPE sheets may increasingly collaborate with other industries such as construction, packaging, and healthcare to create innovative, multifunctional products.

Sustainable Initiatives: With a growing focus on sustainability, HDPE manufacturers will likely adopt eco-friendly production methods and invest in reducing their carbon footprint.

Regulatory Changes: Environmental regulations are becoming more stringent worldwide. This will drive innovation in the field of LDPE sheets, pushing manufacturers to develop more environmentally friendly products and processes.

Advancements in Agriculture: LDPE sheets have a significant role to play in modern agriculture, from greenhouses to irrigation. As agriculture continues to evolve to meet the world’s food demands, LDPE sheets will be part of sustainable and technology-driven solutions.

In Conclusion

LDPE sheets are versatile, durable, and environmentally friendly materials that have found their way into various industries. Their benefits, including flexibility, moisture resistance, and recyclability, make them a reliable choice for a wide range of applications.

The future of LDPE sheets is promising, with the potential for innovations, increased customization, and a strong focus on sustainability. These versatile sheets are not only a testament to the adaptability and durability of plastic materials but also an example of how they can be part of a more environmentally conscious and sustainable future.

As industries and consumers continue to prioritize responsible and sustainable choices, LDPE sheets stand as a practical and eco-friendly option. They are part of the ongoing effort to balance the benefits of plastic materials with the need for environmentally responsible solutions in our ever-changing world.